Industrial Burner Management Systems

Modern industrial operations rely on precise burner management systems – often referred to as combustion control systems – to optimise boiler performance, enhance energy efficiency, and minimise emissions. Among all the equipment in an industrial boiler house, a reliable, digitally controlled burner management system is essential.

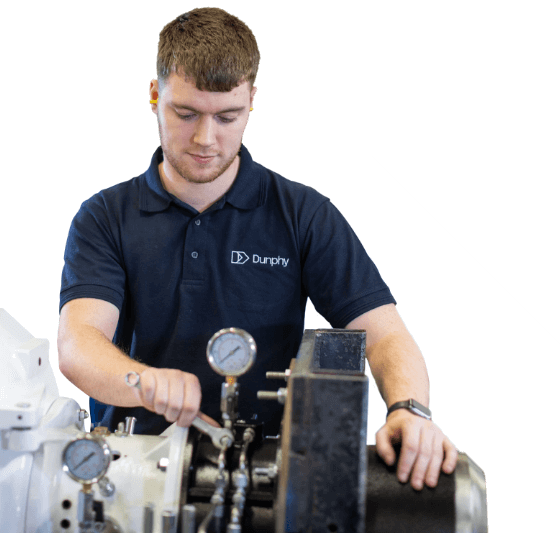

Dunphy has 60 years of expertise in combustion systems and provide a range of systems to sit along side our range of industrial burners.