Gas Boosters

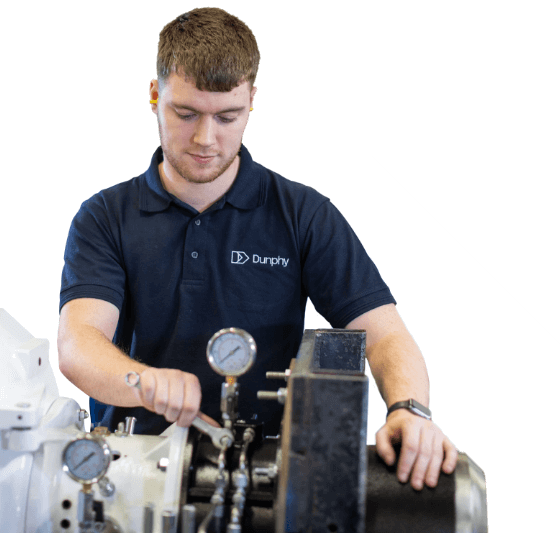

Dunphy provide gas boosters to suit the majority of applications where a robust and reliable solution to the problem of low gas pressure is required. all of these products meet industry gas booster regulations.

As standard, they comprise anywhere from one to three booster units that can provide a pressure lift of up to 82mBar and volumes up to 1300m3/hr. Where there is a requirement for a greater pressure lift or volume, a bespoke range of boosters is available.