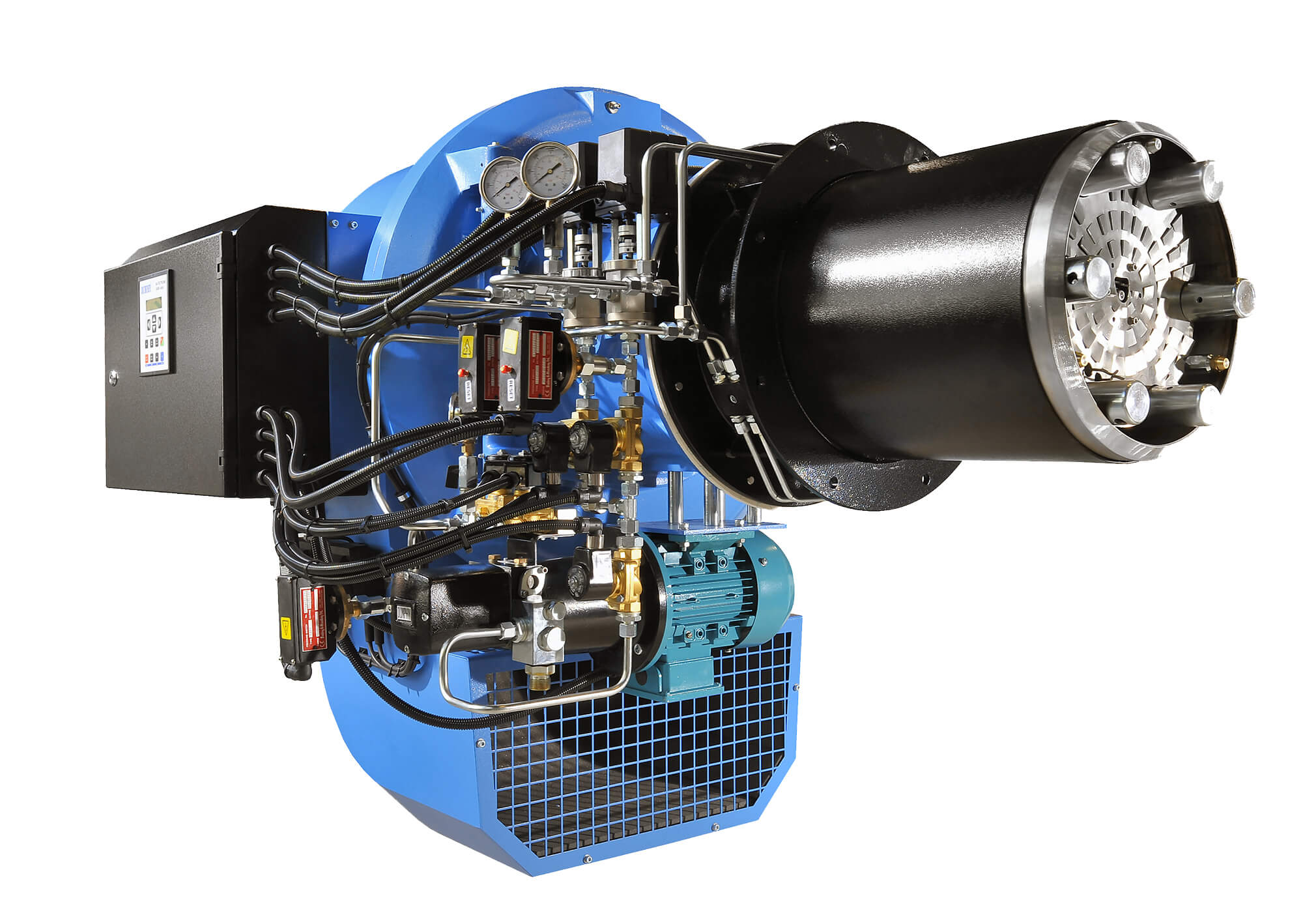

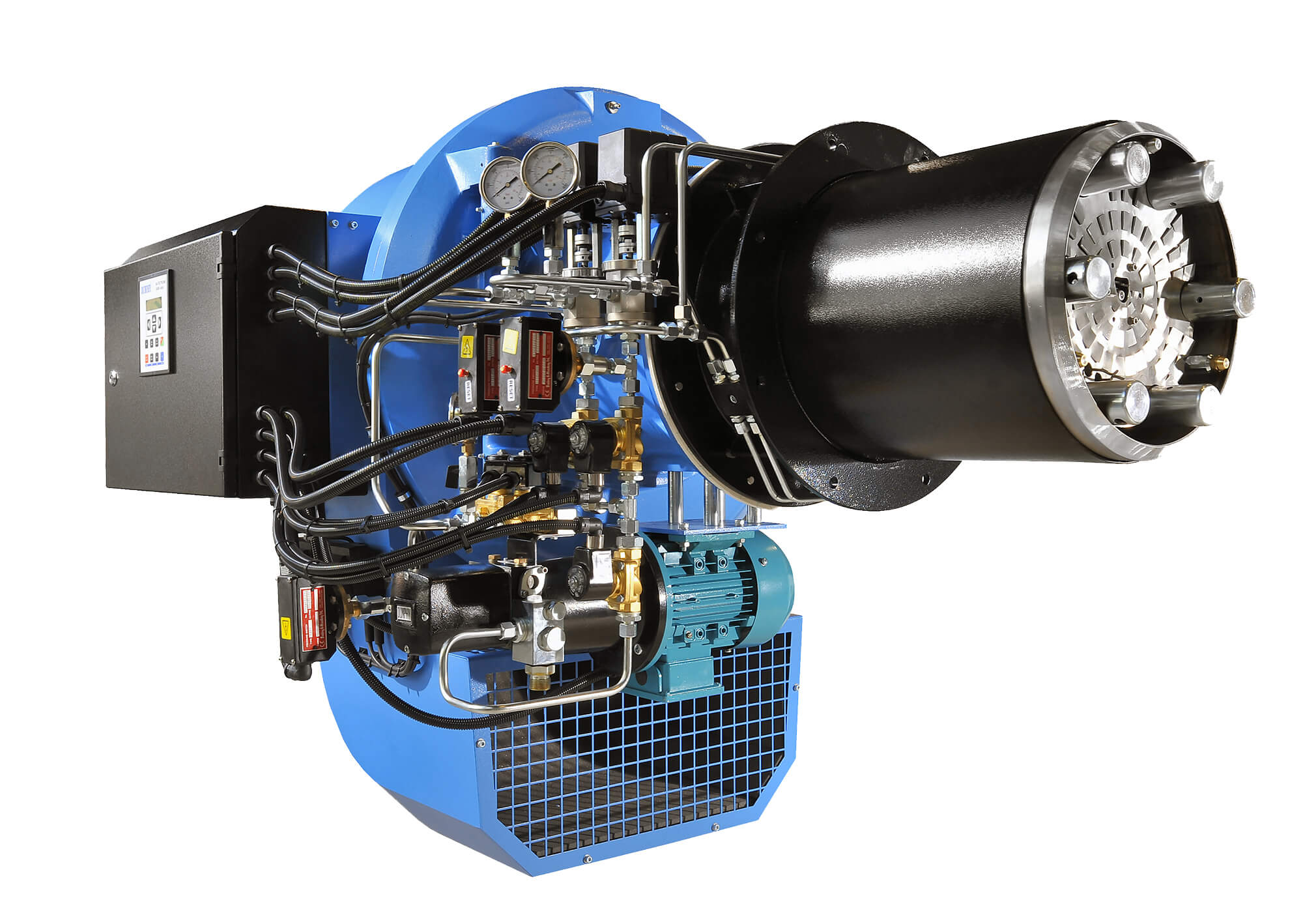

Industrial Oil Burners

Dunphy industrial oil burners can be used with all types of oils, such as:

- Biofuels / Biooils

- B5 to B100

- Kerosene

- Methanol / Ethanol

- Gas oil / diesel

- Medium fuel oil

- Heavy fuel oil

- Synthetic fuels

Dunphy industrial oil burners can be used with all types of oils, such as:

These can be burnt individually, as dual oil burners, and simultaneously fired burners, where two or more oils can be burnt at the same time. The range is suitable for use on all makes and types of oil heat, steam and incineration boilers, furnaces and for process applications.

Oil burner variants are available in the range of 60kW to 60MW.

Low NOx combustion heads will reduce NOx emissions to 120mg/Nm³ on low temperature hot water and 150 mg/Nm³ on steam.

NOx levels less than 120mg/Nm³ can be achieved using flue gas recirculation (FGR).

Steam and air atomisation options are available for increased turndowns.

The standard axial air flow burner, on designs up to 13MW, comprises a robust, cast aluminium housing. The motor is located within the air flow, offering 100% heat recovery from the motor and excellent acoustic attenuation.

A duobloc burner comprises a separate fan and motor and is standard on burners above 13MW or bespoke applications above 60kW ranging all the way up to 60MW. The duobloc burner is used for preheated air, incineration, ducted air, foul air, sluice gate utility burners.

We’re the leading provider of combustion equipment in the UK and have over 50 years’ worth of experience in the industry. This means there’s no better choice for your boiler house repairs. Get in touch with a member of our expert team to learn more.