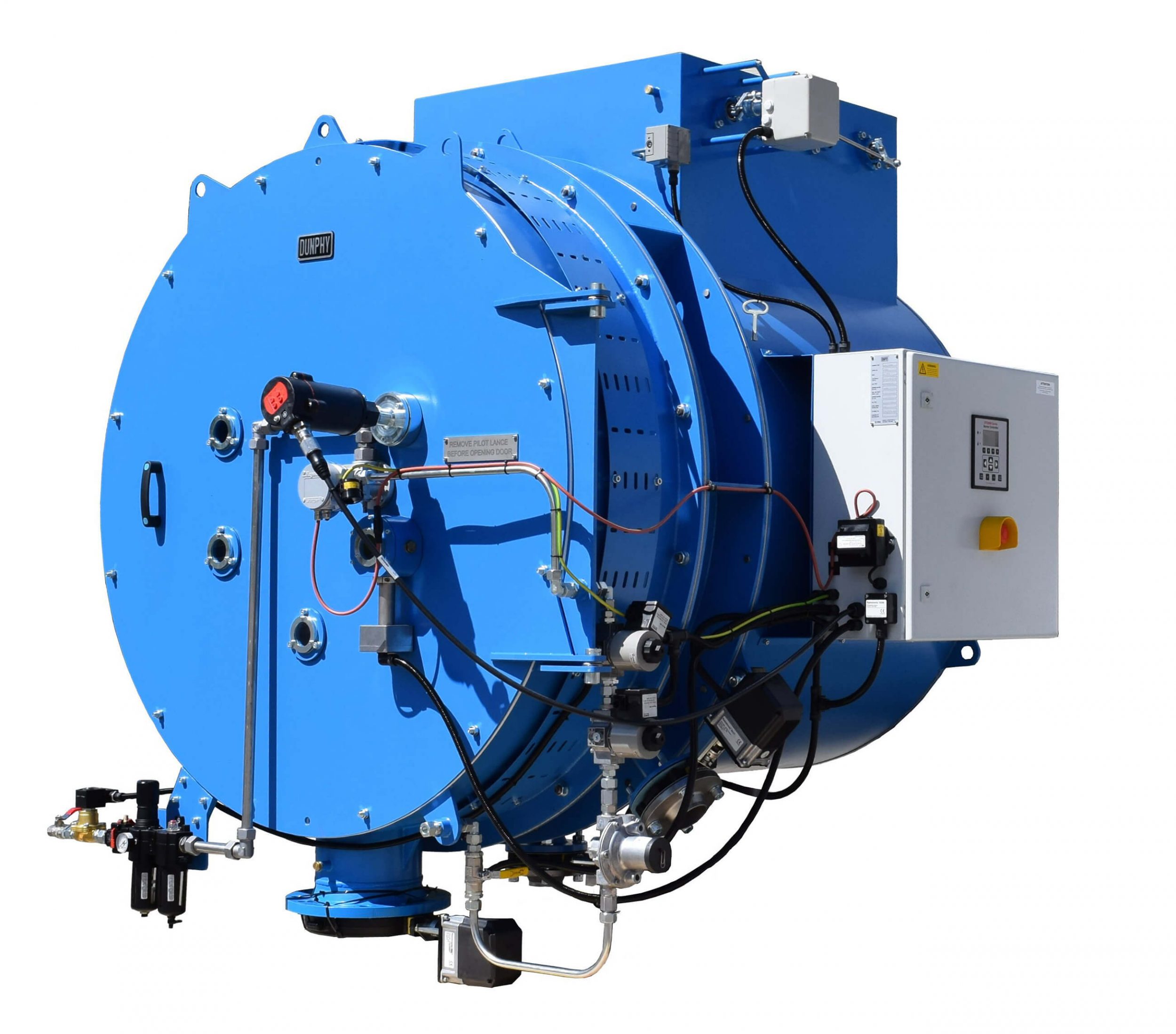

Industrial Gas Burners

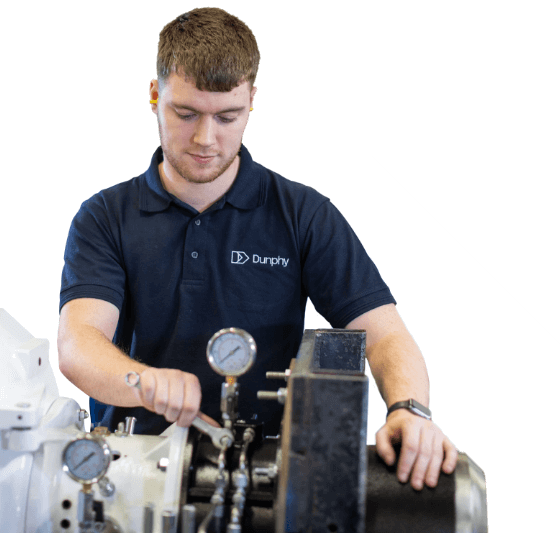

Industrial gas burners engineered to deliver exceptional performance and versatility, seamlessly operating with a wide range of gas types. Whether using natural gas, LPG, hydrogen, biogas, coke oven gas, town gas, or syngas, our burners provide reliable and efficient combustion solutions for industrial applications, ensuring optimal energy utilisation and reduced emissions.