Boiler Sequencing Panels

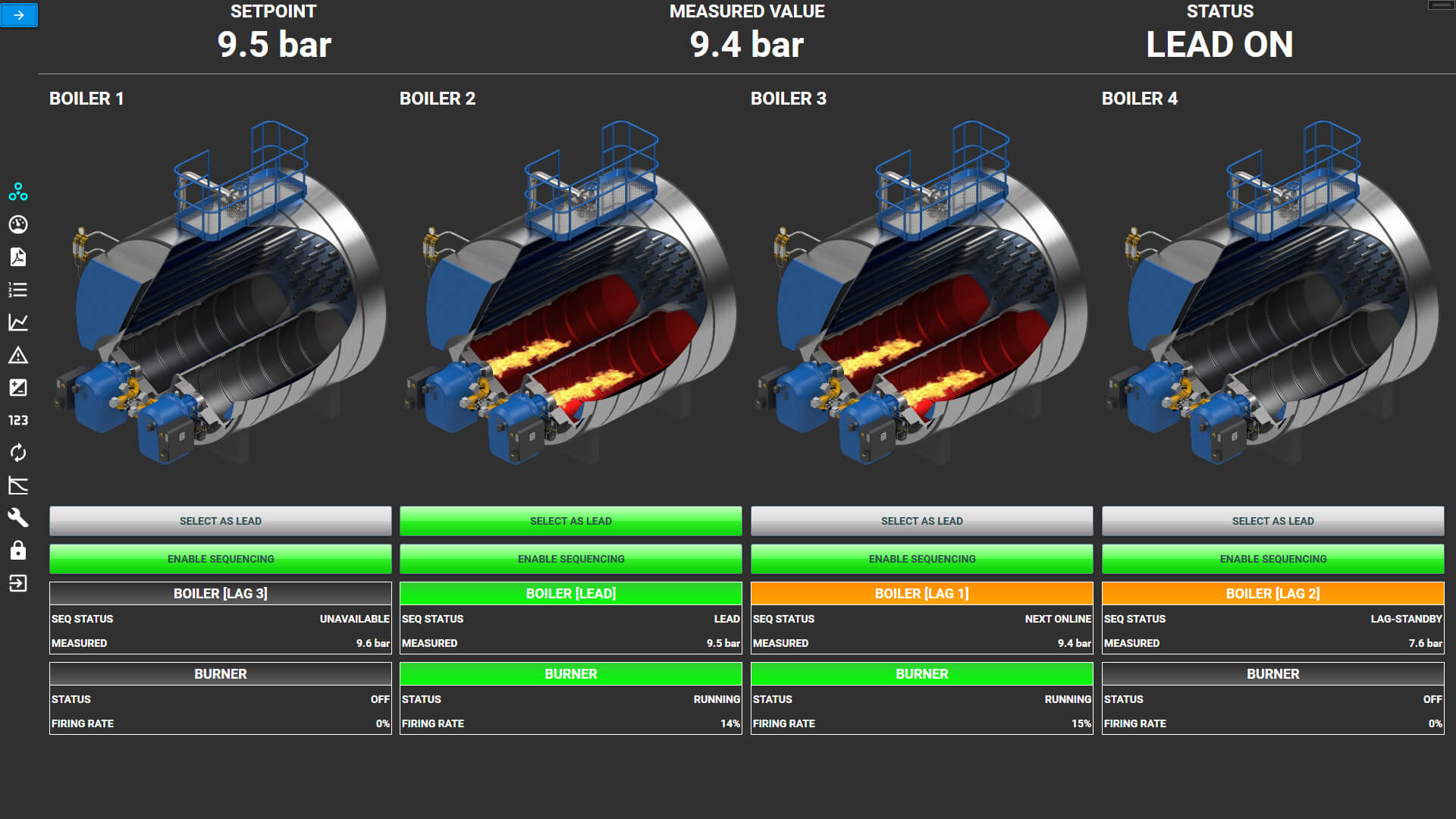

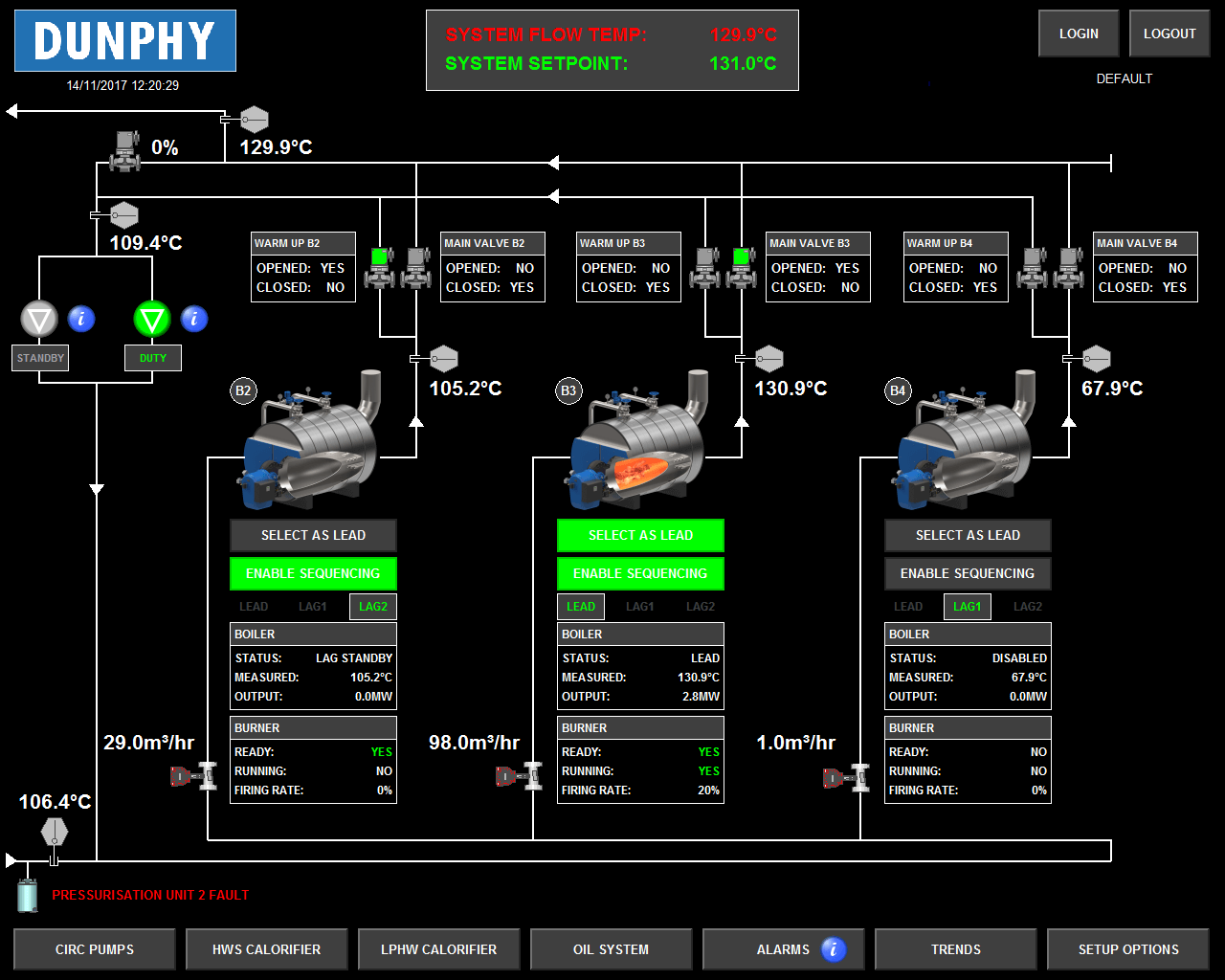

We provide unique, fully configurable boiler sequencing panels that can be customised to suit the needs of your operations. Using a boiler sequencing system ensures that boilers are fired in a controlled manner, providing cost savings by preventing individual boilers from over-firing and cycling on and off unnecessarily.

All of our sequencing panels feature:

- A high-quality panel, designed to the customer’s specification.

- An intuitive design.

- Password protected control of features such as lead boiler selection and setpoint control.

- Auto change setpoints based on the day/hour to provide efficient use of the steam/hot water.

- Autorotation of lead boiler.

- Set a specific sequencing order for each lead boiler.

- Record detailed historical data to suit your own requirements.